In-Room Solutions

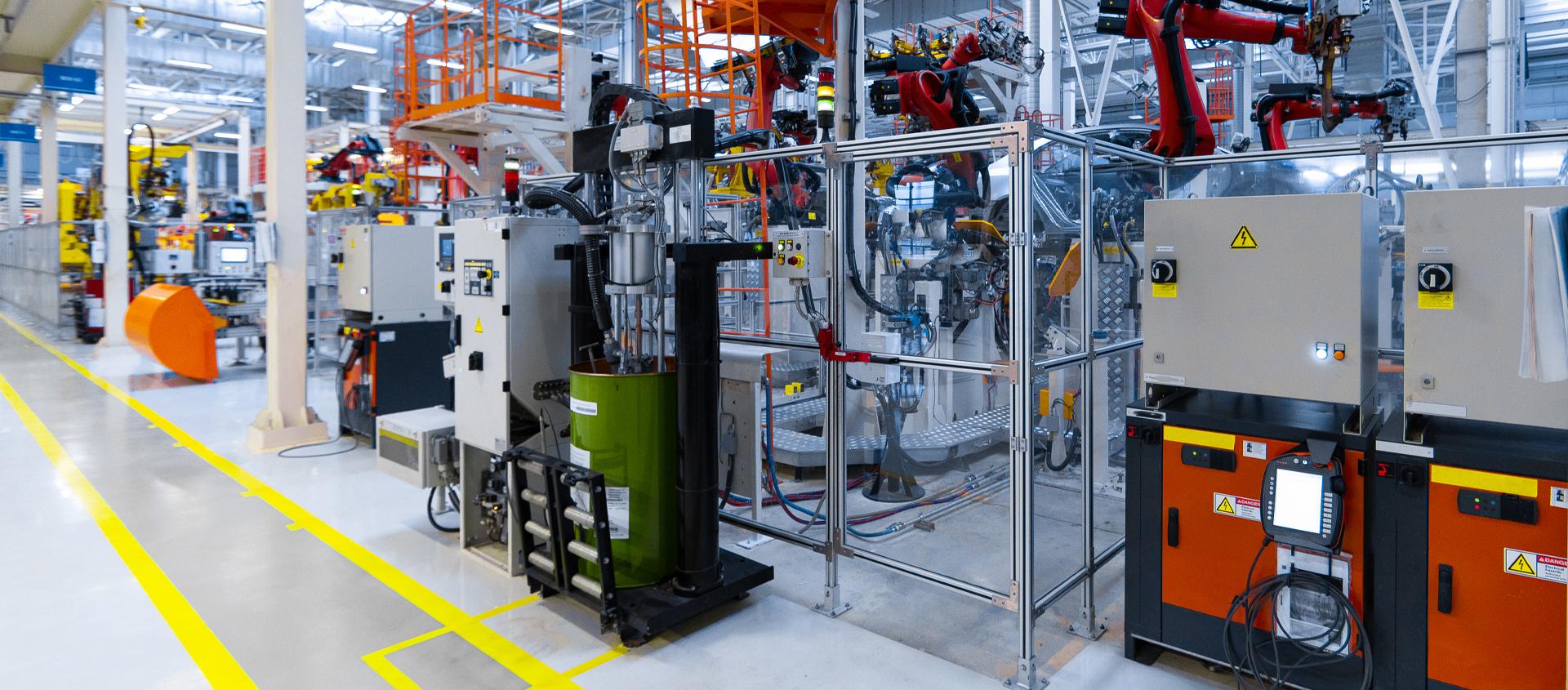

In-room systems are typically used in production facilities such as printing houses, electronics manufacturing or other production areas with heat-producing machinery.

In-room systems can:

- reduce excess heat by adiabatic evaporation

- protect against electrostatic discharge (ESD) by controlling the humidity of the air

- reduce the risk of product desiccation and undesired dehydration

- help alleviate the presence of airborne dust which can threaten production equipment, product quality and the health of people working in the facility

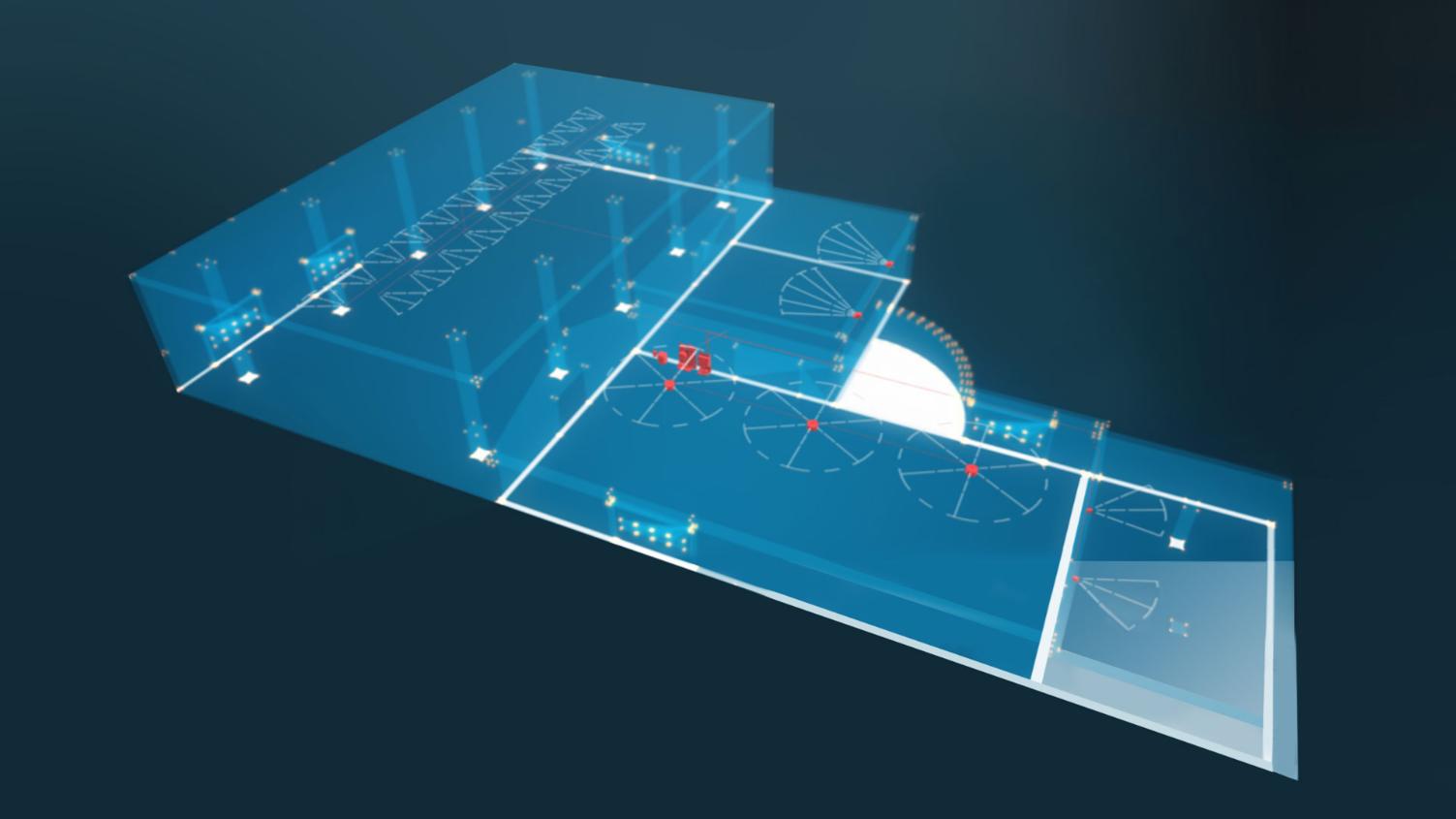

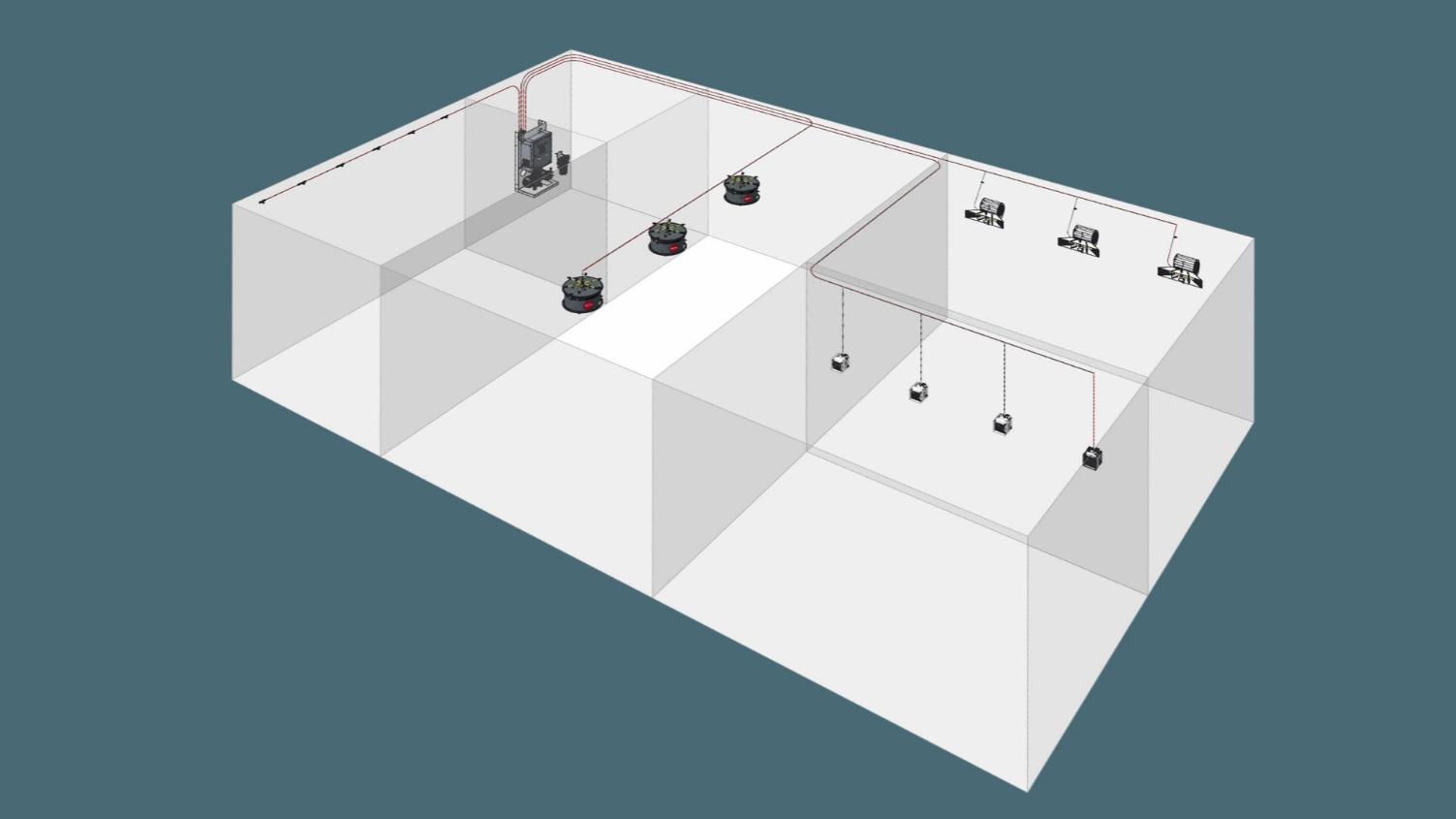

An in-room air humidifying system distributes water mist to different sectors within a production or storage facilities. This illustration shows how some atomizers and nozzles are precisely targeted at a heat or dust source while others deliver humidity to the room entire room or sector.

3D diagram showing a typical installation. From the controlling system components, water is distributed to various zones - here shown using different kinds of vaporizers and atomizers.

System fundamentals

An in-room air humidifying system consists of a water processing unit or units and a controller (HydroSens™) connected to sensors in the production facility itself.

The controller and the pump supply water at 50 bars pressure to nozzles or atomizers in the production facility, producing a finely atomized water mist which rapidly evaporates to the air.

The pump output is controlled by a frequency inverter and a pressure gauge. The combination provides a flexible flow from 1 to 100%. There is no unnecessary heating or by-passing water.

Features

- Low power consumption (from 2.1 watt per liter of water)

- Capacity from 12 to 1200 l/h

- Modulating volume-controlled water flow (PID)

- Ethernet/Modbus standard

- Hygienic design

- 1 to 10 zones humidity control for high flexibility